Technical Timber Flooring Specifications For Professional Stage Flooring

The floor is the base of any construction. Having a house is to create a foundation for living. Among all the other things, the flooring is the part that is the base that is most deeply related to life. Of all the popular options that we have, timber flooring is considered to be the finest and most classy option.

Since it is a material that colors the interior, it reflects the trend and keeps the beauty. Of course, it is also easy to clean.

For babies and the elderly, safety considerations are also necessary. In addition, it is desirable to have a gentle floor on the legs of the pet. Timber flooring lives up to all these expectations.

Table of Contents

The Floor

- The floor consists of an iron frame, from a doublet profile of 200 every 100 cm. Each iron construction is painted in two layers of anti-rust paint or

- SHA to prevent rust. Above the iron construction are the beams of a 5/10 pine tree clipped and sanitized according to the standard, connected, and anchored.

- To the iron construction. Above the wooden beams are plates attached in preparation for the final floor.

Technical timber flooring specifications for professional stage flooring

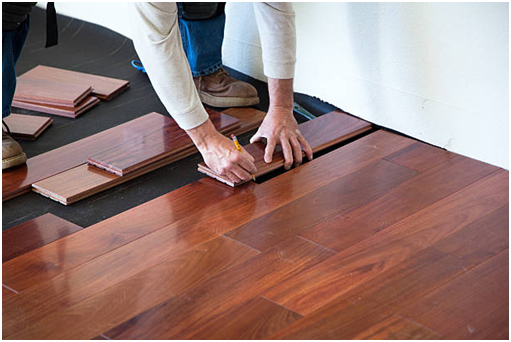

The floor of the stage is expected the stage wood. The contractor will provide the timber flooring specifications for the stage that will meet all the technical requirements listed in the technical specifications and the attached sketches. The work includes supplies, transportation, installation, leveling, painting, and finishing of the floor.

Skeleton

- A structural skeleton made of 5/10 Finnish pine beaks is clipped and sanitized that stands every 40 cm and is wrapped in OSB plates.

- Additional cuts can be combined on-demand and at an additional cost.

Basics of timber flooring specifications

- The foundations consist of concrete plates with a diameter of 40 cm placed on the ground and up to 50 cm high. The

- The number of pillars is determined according to the size of the structure. For example, if a structure of 100 square meters is poured with 12 pillars, then do not screw the concrete-carrying beams to allow flexibility to the floor. Connect to the bottom of the beams 10 mm thick neoprene pillows, a degree of difficulty a-shore 60 with combustion delay.

General specification

The stage carrying capacity will be 750 kg per square meter. The design of timber flooring specifications will be approved by a certified engineer on behalf of the contractor. The concrete floor must be smooth and straight before placing the wooden floor on top.

All parts of the tree (except the stage plates) will be treated with a firebrick 2000 combustion inhibitor ( si 755 level 3) – including local treatment on the ground for cuts in place.

The space’s concrete floor will receive an infrastructure carrying beams from pine wood ms 6-5 in sizes 2″ 4x” allocated (beams 5 10x.) The wooden beams will be high-quality, including impergenitation therapy and anti-pest treatment. The beams will be placed perpendicular to a stage rim at an interval of up to 60 cm. Between which the beams will be connected to widths every 2 m.

The contractor’s responsibility

The contractor’s responsibility will generally be for one year from the time of delivery. The contractor will be responsible for the integrity of the floor (excluding paint treatments) and will perform all necessary repairs without interruption to the ongoing operations of the building.

The contractor will submit execution planning before work begins.

A safety engineer certificate must be provided

Only a professional contractor will be able to work as per the standards and adhere to timber flooring specifications. Its stage panels and closing panels will be handled after assembly in transparent polyurethane lacquer containing a flame retardant) such as a flame anti-denbergloss flame. It is approved by the standards institution of the state and the architect, the invitee, and the consultant. So, make sure that you look for a qualified and certified engineer.

Summary

The floors of facilities where many people come and go require durability. At the same time, a floor is a place that determines the impression of the space, so there is no compromise on beauty. The technology cultivated over many years in the residential field to deliver Strong and beautiful flooring materials that combine both to the facility space.

No Comment